Hand pallet jacks are common moving equipment used by many manufacturers. It is used in pallet transferring and material handling. Unfortunately, even when workers attempt to use them safely, pallet jacks handling is still one of the biggest hazards in today’s working environment. Common hazards associated with pallet jack operation such as overloading of load, mishandling of hand pallet jack and even misarrangement of goods on the hand pallet jack can bring danger to the workers. There are precautions that can be done to reduce the hazard such as safety training, operation training, routine inspection of the jack before use, wearing the right personal protective equipment (PPE), route planning, and avoidance of horseplay. However, the hazards still exist and haunt the workers and the factory owner everyday.

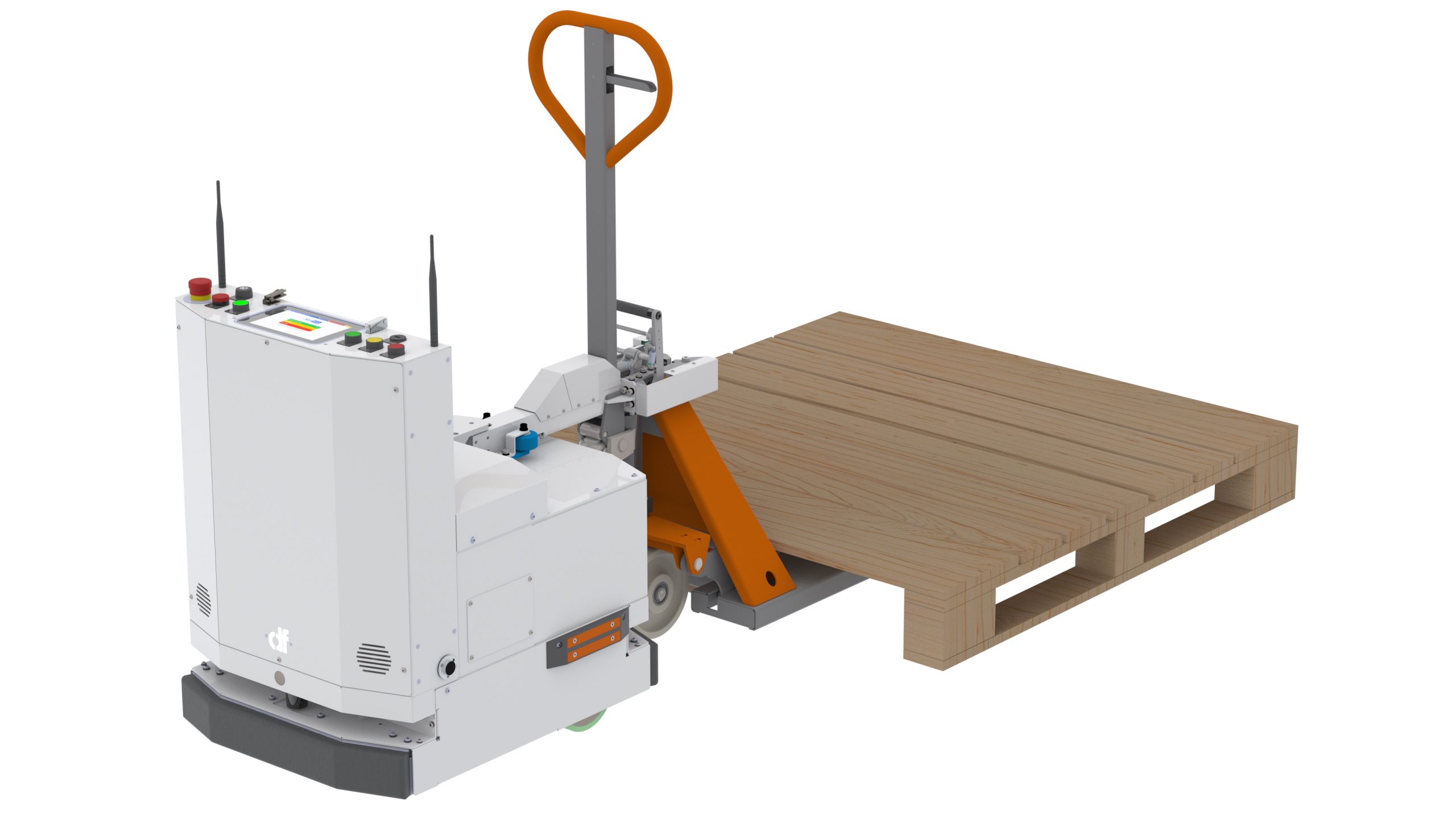

As an alternative, DF Automation & Robotics found an automated solution which can help reduce the hazard, as well as improve the material handling efficiency. Most importantly, The investment is minimal and the existing hand pallet jacks can still be reused. Zalpha Autonomous Mobile Robot is the answer to it. Zalpha AMR is a mobile robot by DF Automation and Robotics which can navigate autonomously by using sensors to identify the surroundings during its operation. Zalpha AMR comes with a flexible top compartment which can carry customized top compartment for different applications. For hand jacks towing, DF mechanical design team have designed a general automated towing clamp which works for most of the hand jacks in the market. Below is the detailed description of the operation of the AMR for hand jacks towing.

AMR Process

Clamp Mechanism

The clamp is an automated lock mechanism designed specially for hand jacks engagement. It comes with a sensor which can trigger the lock whenever the hand jack is properly attached to the clamp. It can be manually disengaged as well. Users can disengage the handle from the actuator movement by pulling the release handle to unhook.

Pallet Jack Guide

A Pallet Jack Guide guides and holds the pallet jack’s front wheel in position. The aluminium plate will correct the front wheel angle and guide toward the U-shape plate. Once the wheel enters the space, it will hold the pallet jack in position.

Advantages of Automated Pallet Jack Clamping

By using Zalpha Pallet Jack clamping, the working hazard is reduced as it minimises the handling of the goods by humans. The material handling operation can be easily planned and predicted as well since the operation is automated. Besides, it can also significantly increase the operation time without need to worry about the tiredness and absence of the workforce.

For more detail of how it operates, please find the following video link

Video 1: Zalpha AGV Robot with Automated Clamping Mechanism on Pallet Jack

The Zalpha AGV is equipped with an automated clamping mechanism designed to secure a standard pallet jack without requiring any modifications to the jack itself. This AGV autonomously clamps onto a pallet jack, transports the loaded pallet to its destination, releases the pallet jack, and proceeds to perform other tasks—all accomplished fully autonomously.

Author by: Chia Chin Wee I Muhammad Sofwan Bin Zamri